Energosteel at MS Excel – Everything you need to know for successful work with data training

Visit of “Energosteel” to Armenia

Earlier we considered a mixture of which materials is used in cement production. The base of this mixture is a clinker. In this article, we will consider the composition of clinker and its impact on grinding balls deterioration in milling process.

Clinker (in cement industry) is transitional product in cement production. Upon heating mixture obtained from limestone (about 75%) and clay (about 25%) partial melting occurs and clinker granules are formed. Clinker and gypsum (about 5 %) are mixed and finely milled to obtain cement. Gypsum control the setting properties of the cement. It can be partially replaced by other forms of calcium sulfate. Some technical conditions allow adding other materials. A typical clinker has an approximate composition: CaO -67%, SiO2 – 22%, Al2O3 – 5%, Fe2O3 – 3%, and 3% of other components.

The base minerals contained in clinker:

- Alite (C3S = 3CaO*SiO2) is a soft material, Mohs hardness is 3.2–3.4, the mineral is very fragile and easily damaged.

- Belite (C2S = 2CaO*SiO2) is the second major mineral of Portland cement clinker, it characterized by a slow hardening, but provides achieving high strength during long solidification of Portland cement. Mohs hardness is 5-6.

The more belite, the harder to grind clinker.

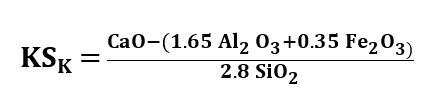

Factor of clinker saturation (KSK) characterizes the incomplete saturation of silica with calcium oxide during clinker formation. It calculated from the ratio of the difference in total CaO content without the sum of Al203 + Fe203 and S03 to the Si02 concentration with the corresponding coefficients — the molar ratios of each oxide to CaO.

For calculation of factor of saturation used Kind V.A. formula (1).

Value KSK = 92 % indicates that clinker is medium grinded, KSK > 92% – easy to grind, KSK <92% – hard to grind. The lower value KSK, the larger the clinker. Typical KSK values in Portland cement clinker are 0.8-0.98, or 80-98%. The value KSK of ordinary Portland cement is 90-95% and 95-98% of high strength Portland cement. The higher value KSK, the lower the grindability.

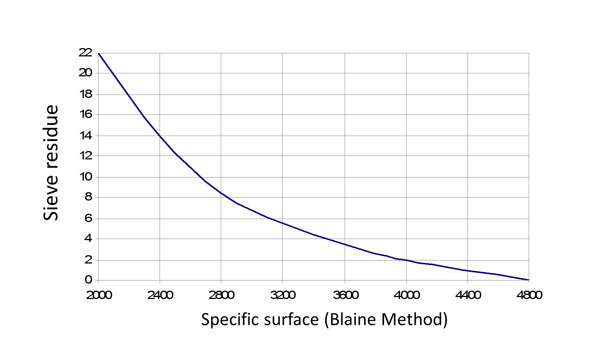

In addition to the physical and chemical characteristics of clinker, the required grinding degree (grinding fineness) also affects grinding balls deterioration. Blaine’s specific surface area (cm2 / g) mainly used abroad. Sieve residue (in percentage) used in Ukraine and CIS. In modern conditions, the laboratories of many cement plants use both indicators. Their dependence is shown below in the graph.

The larger required grinding fineness, the larger grinding balls deterioration.

In addition to the above, many other factors directly affect the specific consumption of grinding balls. The most significant factors are below:

- With the growth of the silicate module, SiO2 / (Al2O3 Fe2O3), the grindability decreases.

- With the growth of Al2O3 grindability increases.

- With the growth of Fe2O3 grindability increases.

- With the growth of clinker density grindability increases.

- The higher raw mixture density, the worse grindability.

- The higher C3S (alite), the better grindability.

- The higher C2S (belite), the worse grindability.

- The more liquid phase, the worse grindability.

Clinker grindability is determined by quantity of electricity consumed for grinding (kW / ton) under other equal conditions. In cement production entire crushing and grinding process consumes about 85% of the electricity. At the same time 75% of electricity consumed for milling and only 2-20% of them consumed for grinding. According to some hypotheses, only a thousandth blow of the ball is spent on grinding the material. Thus, cement plants are among the most demanding for grinding balls quality customers of company Energosteel.

For over ten years, we have been supplying our partners with an exceptionally high-quality ball, providing the necessary grinding fineness with the minimum specific consumption.