manufacturing

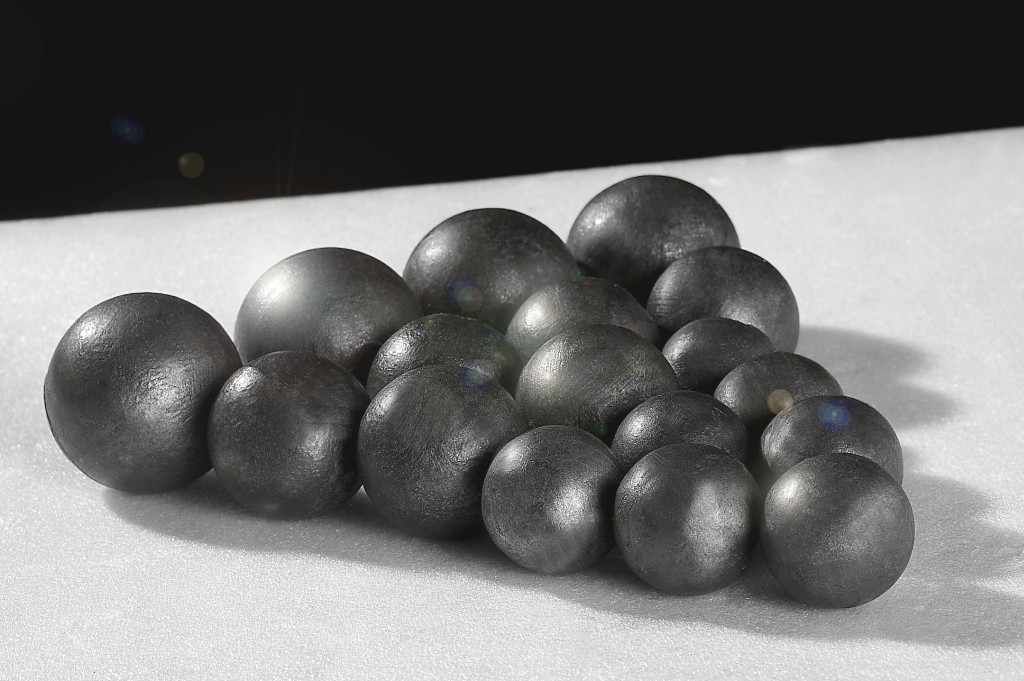

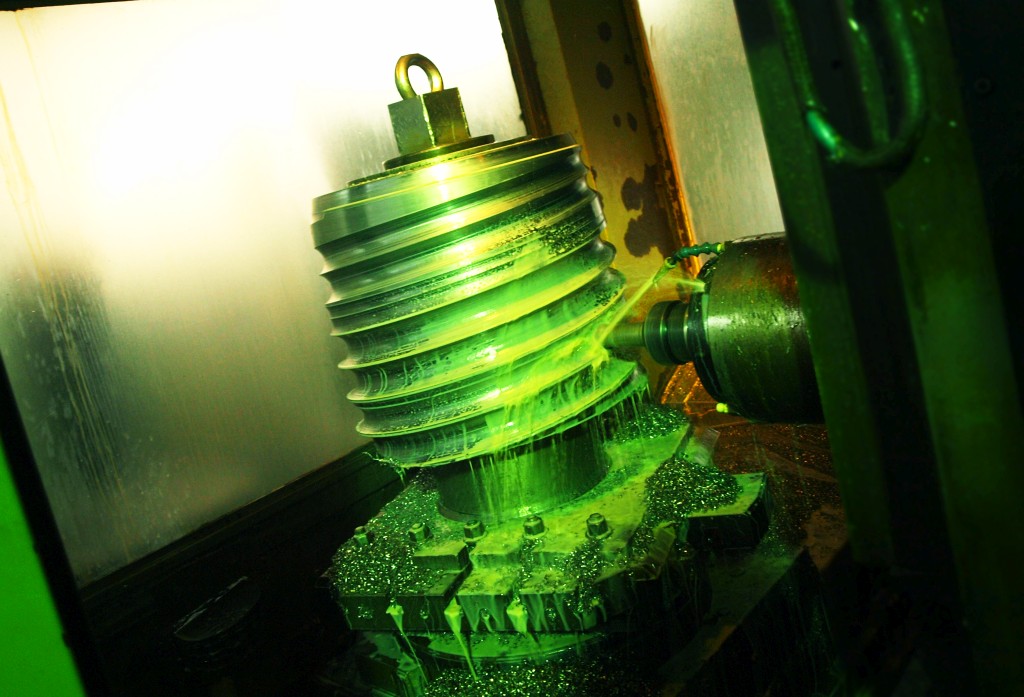

METHOD OF BALLS ROLLING ON BALLROLLING MILLS IS ONE OF THE MOST

MODERN PRODUCTION METHODS

Transversal rolling of balls from the round bars is economical. It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 10-15% to reduce the consumption of metal.

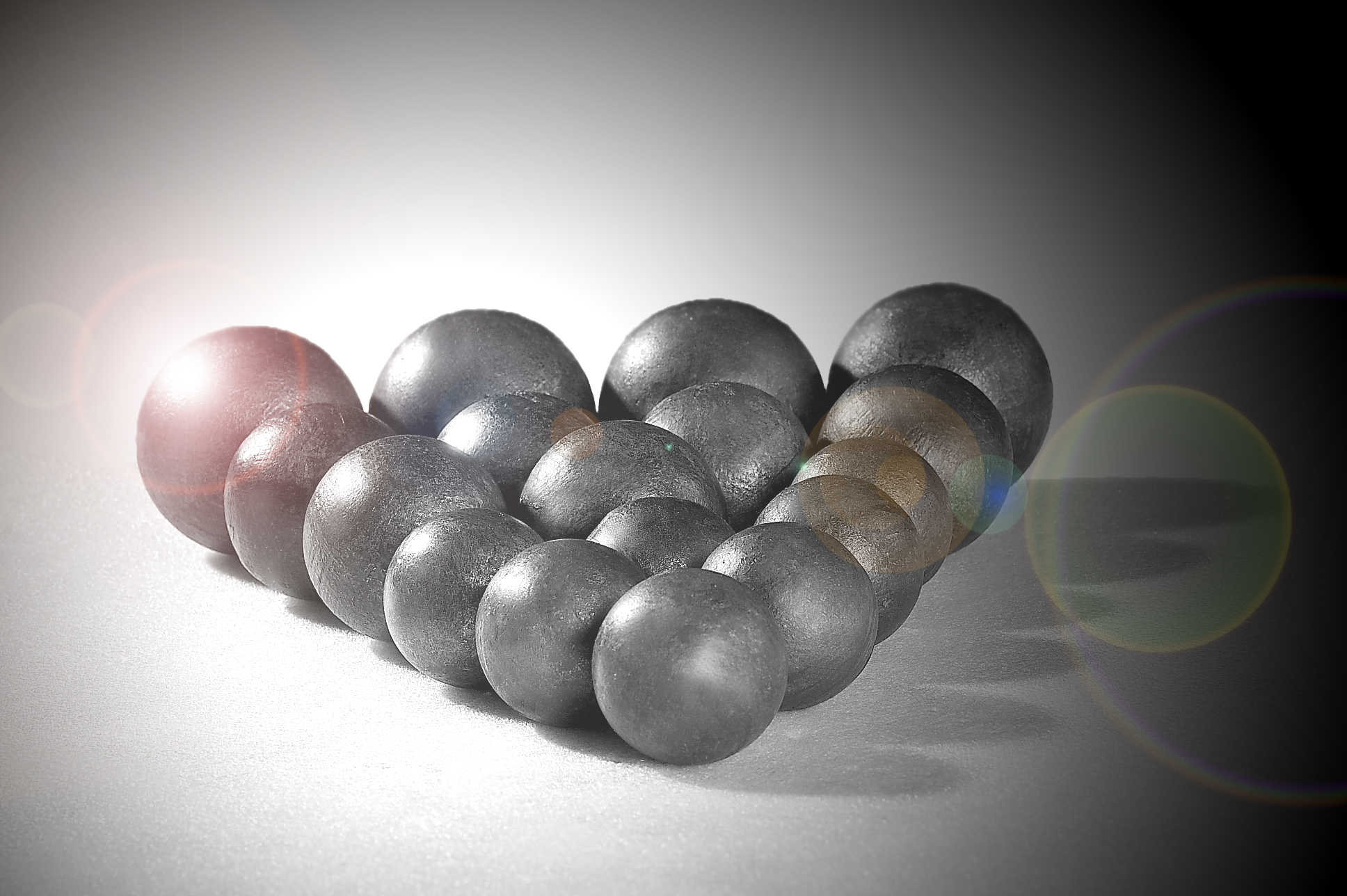

We believe that steel production can be not only efficient but also responsible. That’s why we launched EcoBalls — a new generation of steel grinding balls made exclusively from recycled steel (scrap metal). Click here to read more.

We produce high-hardness grinding balls that do not break when working in a ball mill and do not reduce the service time of the lining boards of the mill drum.