Our steel grinding ball production plant is constantly improving, and now we are happy to announce main technical upgrades in our laboratory! We have two innovative high-precision machines that increase the efficiency of the ball hardness control process.

An automatic hardness tester that differs significantly from previous version. It is fully automated and has several important advantages: saving all previous measurements, automatic calculation of the average value, and the ability to print reports with detailed measurement information.

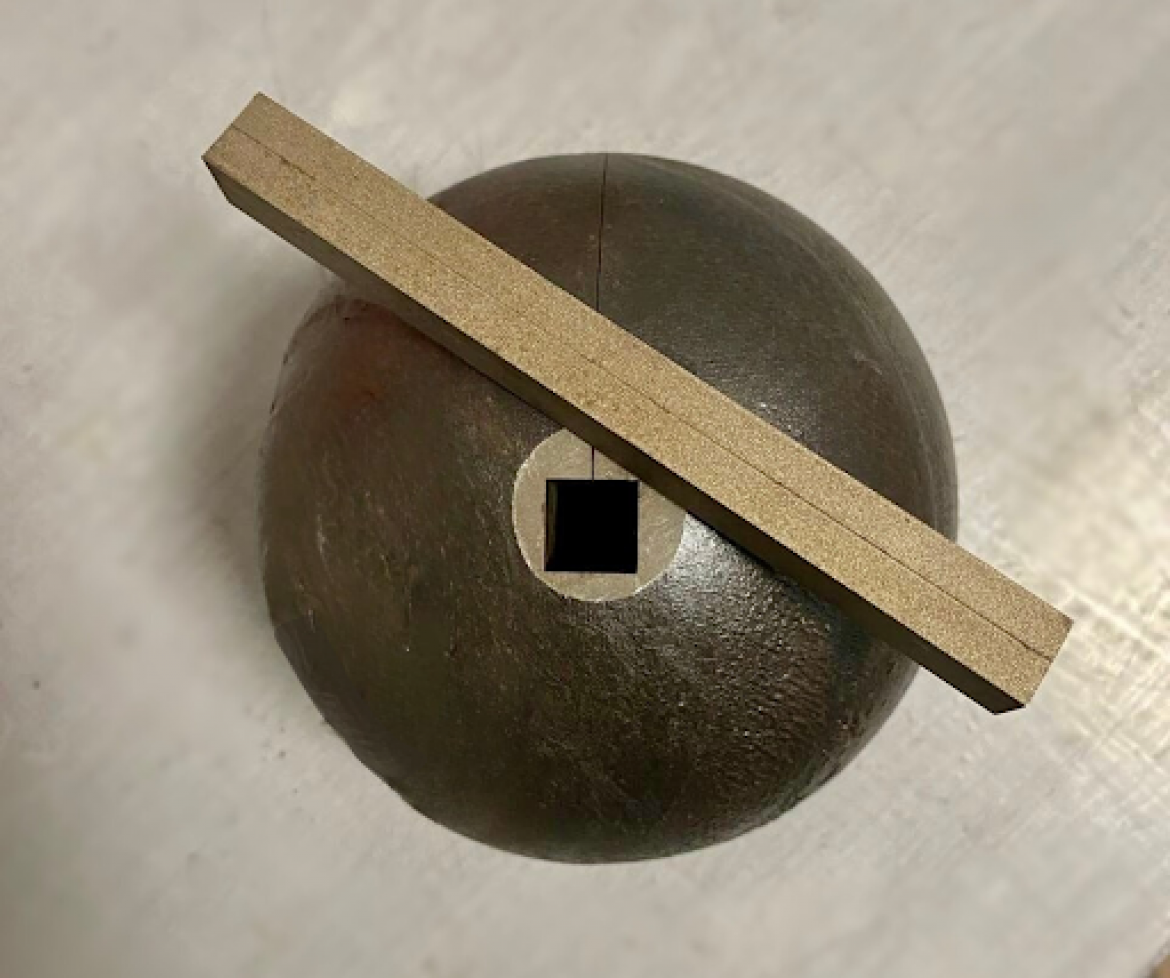

Another significant improvement is the introduction of an EDM wire-cutting machine for preparing balls for hardness testing. This machine partially replaced a polishing machine that was previously used for similar purposes. The main advantage of the EDM machine is its ability to cut the ball in half and obtain a core for measuring the volumetric hardness much faster. For comparison:

- Preparation of a 120 mm diameter ball with the help of polishing machine for measuring volumetric hardness took 48 hours.

- The same process on the new EDM machine takes only 6 hours.

This is an impressive time savings, which allows us to obtain measurement results much faster and respond quickly to possible but unlikely deviations.

We remind that the measurement of the surface hardness of the balls and general quality control is carried out every 2 hours during the rolling of a new batch. Thus, we can guarantee compliance of products with standards and ensure stable quality.

Our plant always follows strict standards. With the introduction of this modern equipment, we are taking another step towards automation, minimizing the human factor. Our goal is not only to meet the highest standards, but also to be a leader in the production of steel grinding balls.