The material science and steels heat treatment. Investigation methods the metals and alloys structure

The metals and alloys structure distinguishes by: the macrostructure, the microstructure and the fine structure. There are three methods for their investigation: Macroscopic analysis Microscopic analysis […]

The material science and steels heat treatment. Historical information on the materials science development

Material science is an applied science studies the interrelationships between the metals and alloys composition, structure and properties under different conditions. Studying this discipline allows the […]

The material science and steels heat treatment. The steel tempering

The steel tempering – is a heat treatment process, when steel heated to a critical temperature and rapidly cooled. This treatment purpose is to increase the […]

The material science and steels heat treatment. High-temperature thermomechanical treatment (httt)

The rolling process of “Energosteel” grinding balls corresponds to high-temperature thermomechanical treatment significantly increases the products strength and hardness. HTTT provides the austenite deforms in thermodynamic […]

The material science and steels heat treatment. Metal treatment type “the rolling”

The rolling consists in billet compressing between the rotating rolls. The billet retracts between the rollers by friction forces, and the pressure forces reduce the transverse […]

The material science and steels heat treatment. Types of the metal treatment

The metals treatment by pressure based on their ability to plastically deform under certain conditions, as a result of external forces influencing on deformed body (billet). […]

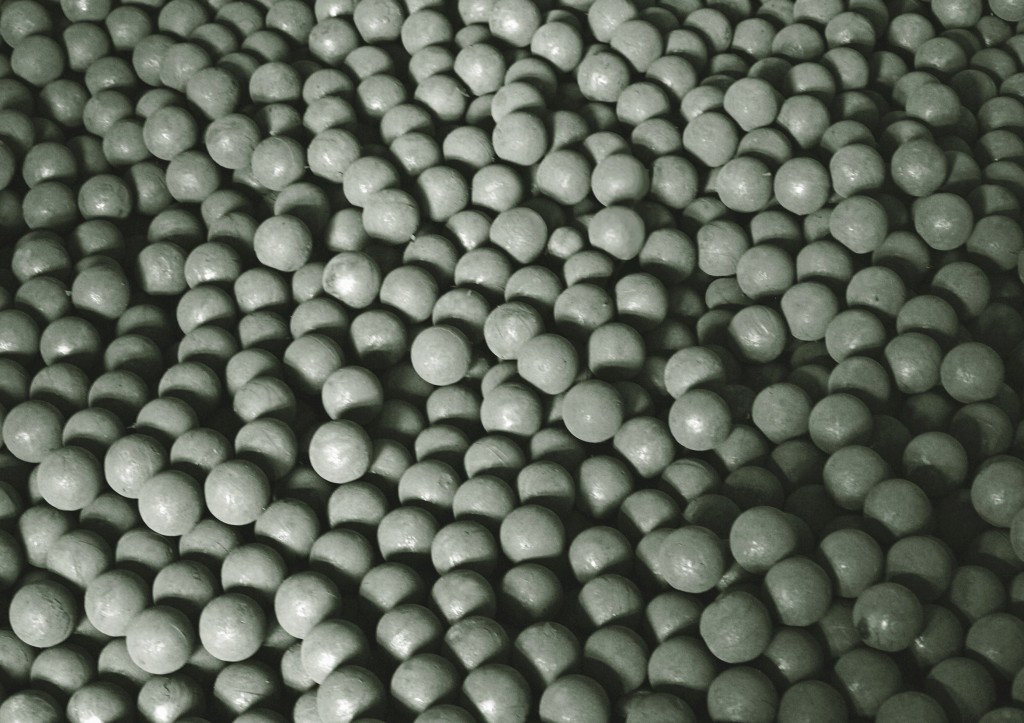

The grinding balls bulk weight in mill without unloading grinding media

As we have written it before, there are two methods for determining the grinding balls bulk weight in a mill: Method with complete grinding media discharge […]

The grinding balls bulk weight in fully unloaded mill

In the previous article we considered the method for determining the bulk weigh of new grinding media. Determination the grinding balls bulk weigh directly operating in […]

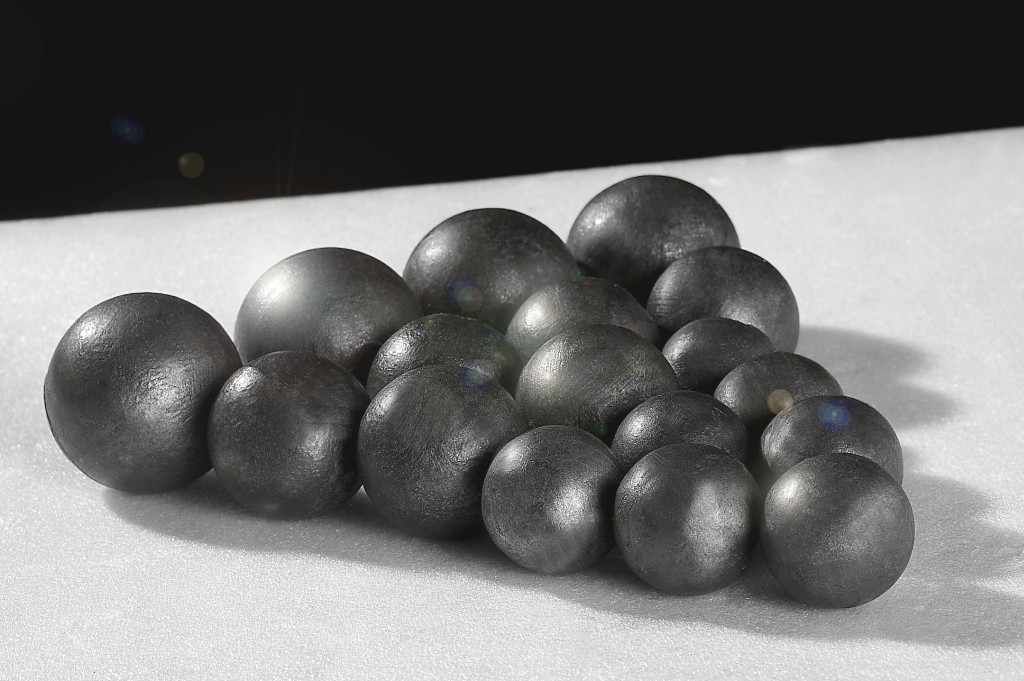

Technological process control of forged steel grinding balls production

Technological process control of forged steel grinding balls production carried out by the shift supervisor and testing laboratory assistant in accordance with the technological control scheme […]