The enterprises consumers grinding media have a question about right choise the grinding ball size (diameter) for the mill in order to achieve the required grinding quality. We noted earlier, this information can be obtained from several sources:

– Technical documentation. It attached to the milling equipment (mill). Each mill manufacturer recommends certain grinding media type for mill operation under certain conditions: the crushed material parameters, the mill’s performance, the raw materials particle size in the mill’s “feed”, and the required grinding fineness (finished class content).

– Past experience of a ball mill. It is possible to calculate the grinding media average diameter formed in the mill operation, during grinding media unload from mill (the grinding balls bulk weight in fully unloaded mill).

– Other enterprises. It is possible to obtain the necessary data on a grinding media granulometric composition from other enterprises with a similar grinding process, including similar requirements to the grinding quality.

Sometimes, the above sources use is impossible.

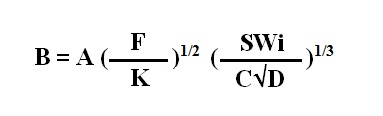

There is a mathematical solution to this problem – the Bond formula. It uses to help determine the grinding media optimal size must be loaded into the ball mill for proper operation ensure. The calculation formula is below:

B – the grinding balls diameter, mm;

A – the correction factor (for grinding balls A = 20,17; for cilpence A = 18,15);

F – the feedstock grain size in 80% of the material, μm;

K – the grinding correction coefficient (for wet grinding – 350; for dry grinding – 355);

S – the grind material bulk mass, g/cc. It is a tabulated value.

Wi – specific energy consumption, kW*h/ton;

C – the mill drum rotational speed,% of the critical speed;

D – the mill internal diameter, m.

At result B = 25mm or less necessary to use the correction factor 1.3, i.e. the grinding balls average diameter should be 32.5 mm in the feed mixture. We draw your attention, a larger grinding balls need to use for future loads. As practice shows, the difference between the grinding balls average diameter in mill and loaded grinding balls diameter is 10-15 mm. In our example, the grinding balls diameter needed to load into the mill must be equal to 40-50 mm.

Let’s sum up. The grinding balls diameter determined by the Bond formula has a recommendatory character and serves as a starting point for calculating the necessary proportion grinding media feeding a new mill. More precisely adjust the ball load in the mill can only by industrial test performing. During the industrial tests necessary to accurately monitor the grinding quality, mill productivity and other technological parameters adopted at the enterprise.