As we informed you earlier, the steel grinding balls produced by Energosteel Company can be used as grinding media in ball mills, regardless of the armor plates material (steel or rubber).

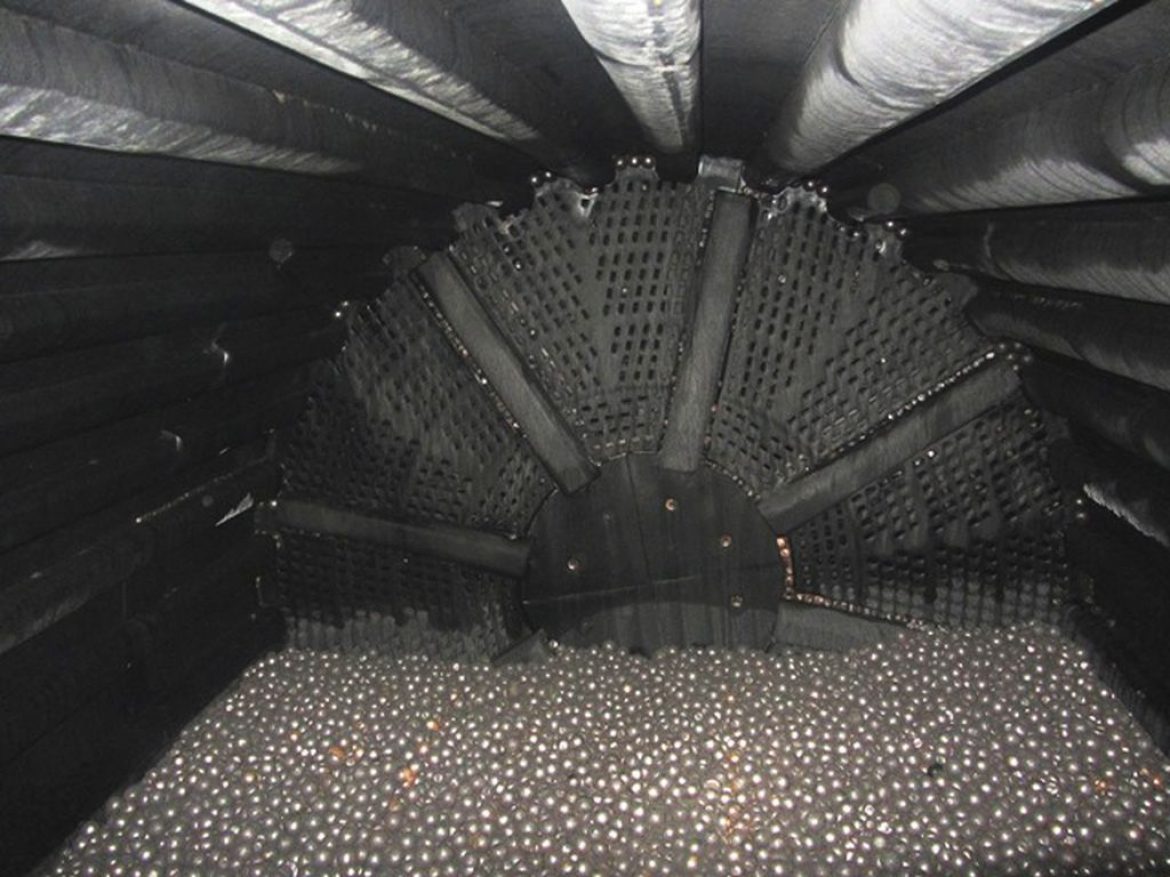

Technical specialists of Energosteel Company constantly contact with customers, in order to obtain feedback on the grinding balls quality, information about our customers’ plans for changing the grinding process parameters. We have found out, one our partner, who has been cooperating with us for more than five years and use 30-40 mm steel grinding balls the fourth hardness group, decided to change the steel armor plate for rubber armor plate in the beginning of 2018. The client has changed armor plate type. He has previously used the armor plates with lifters and he has changed it to the “wave” armor plates type. This armor plate type will ensure the transition from a mixed motion mode of grinding balls to a cascade motion mode. We have provided all information confirms the rubber armor plates use doesn’t affect to the Energosteel steel grinding balls work quality in any way. Energosteel Company specialists have announced benefits the client will receive during use this armor plate type:

- reduction of the grinding media specific consumption ;

- increase the armor plate service life;

- reduction the power consumption, needed for the mill rotation.

All grinding technological parameters are normal after one month of mill operation with a new armor plate. We have noted the actual grinding balls consumption reduction in comparison with the planned norm.

We understand, one month is not enough to reveal all the advantages at grinding balls using in combination with a rubber armor plate the “wave” type for material grinding. We will continue to inform you about this experiment in our next publications.