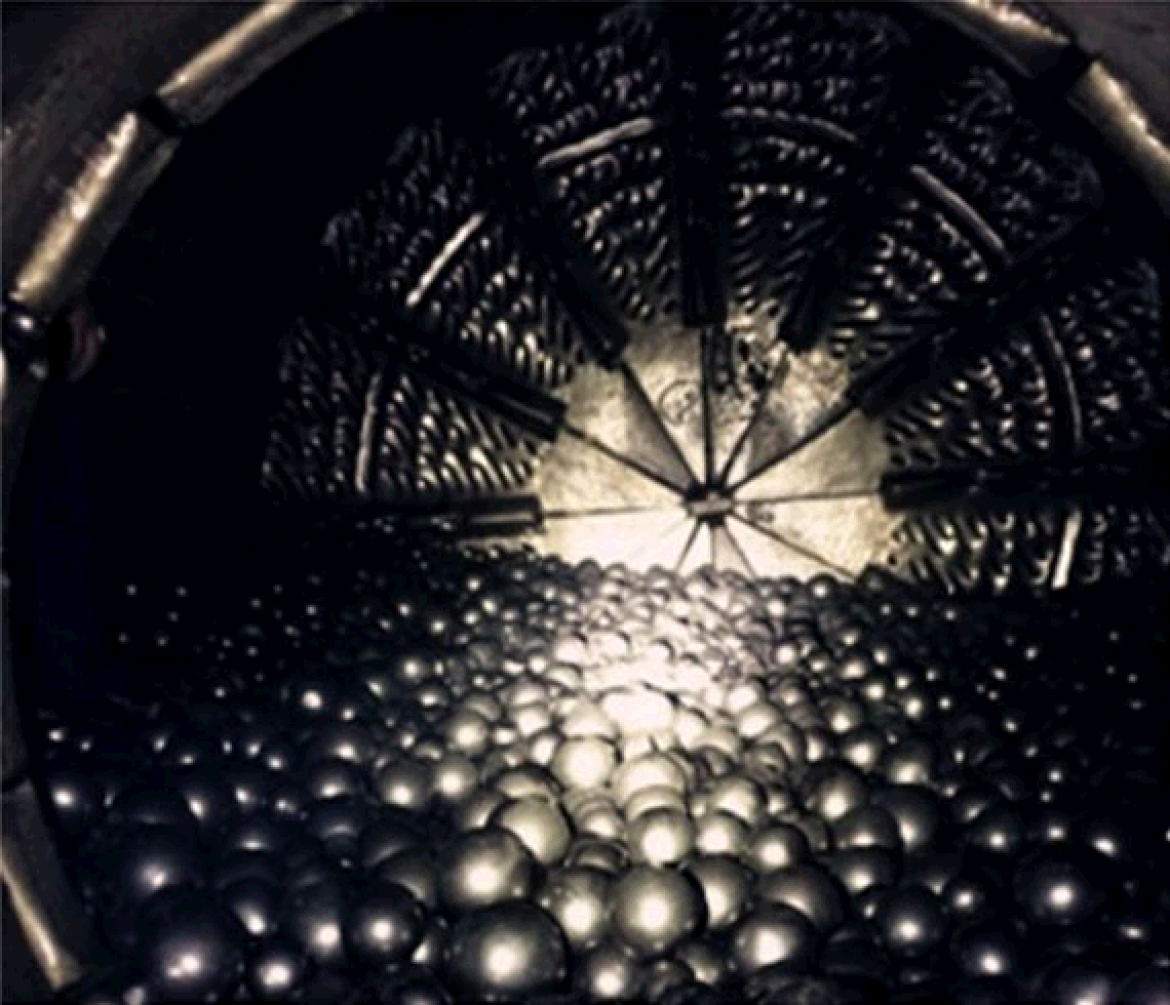

The widespread view that the oxidation process has a significant impact on the grinding balls consumption when wet grinding at the mining and processing plants recently. Cast grinding media producers use this argument often. We will try to look into the matter.

Of course, oxidation process of grinding balls, especially steel grinding balls when wet grinding (free of corrosion resistant chemical additives) might be the case. Mainly, this is determined by water pH rate, used in the enterprise.

The steel and cast iron chemical composition is most often introduced chromium, nickel, aluminium and silicon to minimize the corrosion process. The existence of these chemical elements in sufficient quantities provides steel and cast iron water-resistant in wet environments, in solutions of many acids and alkalis and in the dry gases at high temperatures. When the carbon content is high, the erosion resistance of steels increases. However, in some cases, the erosion proof is high when carbon content is low and the existence of the alloying elements. We use in our production just such a manganese, nickel and chrome doped steel.

Grinding bodies’ corrosion so small that it does not actually affect the total grinding media depreciation in the ball mill. According to some experts, only 2-3 per cent of the specific depreciation of grinding balls is caused by corrosion.

High-chromium cast iron has a maximum corrosion resistance through the oxidized films formation on its surface. But please note that the cost of such grinding balls exceeds the cost of steel grinding balls. The money/value ratio outweighs the balance in favour of steel grinding balls choice. The market structure of grinding media proves it: steel grinding balls taking the lion’s share.