Let’s consider one more index that measures the physical-mechanical parameters of material that is planned to grind in ball mill.

The abrasiveness index is addressed in this article. This index is necessary to forecast the speed of metal abrasion into the milling drum of the ball mill: grinding media, lining, pin etc.

Material abrasiveness depends on specific conditions of the interaction between the material pieces and the metal in the grinding process. In determining abrasiveness index in laboratory conditions, it’s very important to follow all technological parameters of grinding chain. There are material selection, that is planned to grind, the parameters of water, rotational speed of drum, steel mark, the metal elements from which will interact with material.

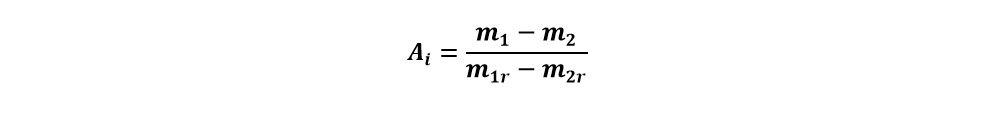

Let’s consider the standard valuation methodology. The installation, which consist of the rotating drum, is used. The dry material samples in size -19+12,7 mm and steel plate enshrining onto the shaft are loaded into the drum. The time it takes for test is 15 minutes and more. The abrasiveness index is calculated upon the formula:

where m1 and m2 – the pre-test and post-test mass of steel plate, g;

m1r и m2r – the pre-test and post-test mass of steel plate with the reference material, g.

To sum up, we can say that abrasiveness index is very important in design for the production even though it is quite simple in calculations. Let’s not forget about it!