QUALITY CONTROL

A quality control system has been implemented at the Energosteel plant. A certified metals laboratory ensures that billets comply with geometric parameters and chemical composition requirements. It also performs quality control of grinding balls, enabling product testing in accordance with international standards before delivery to consumers.

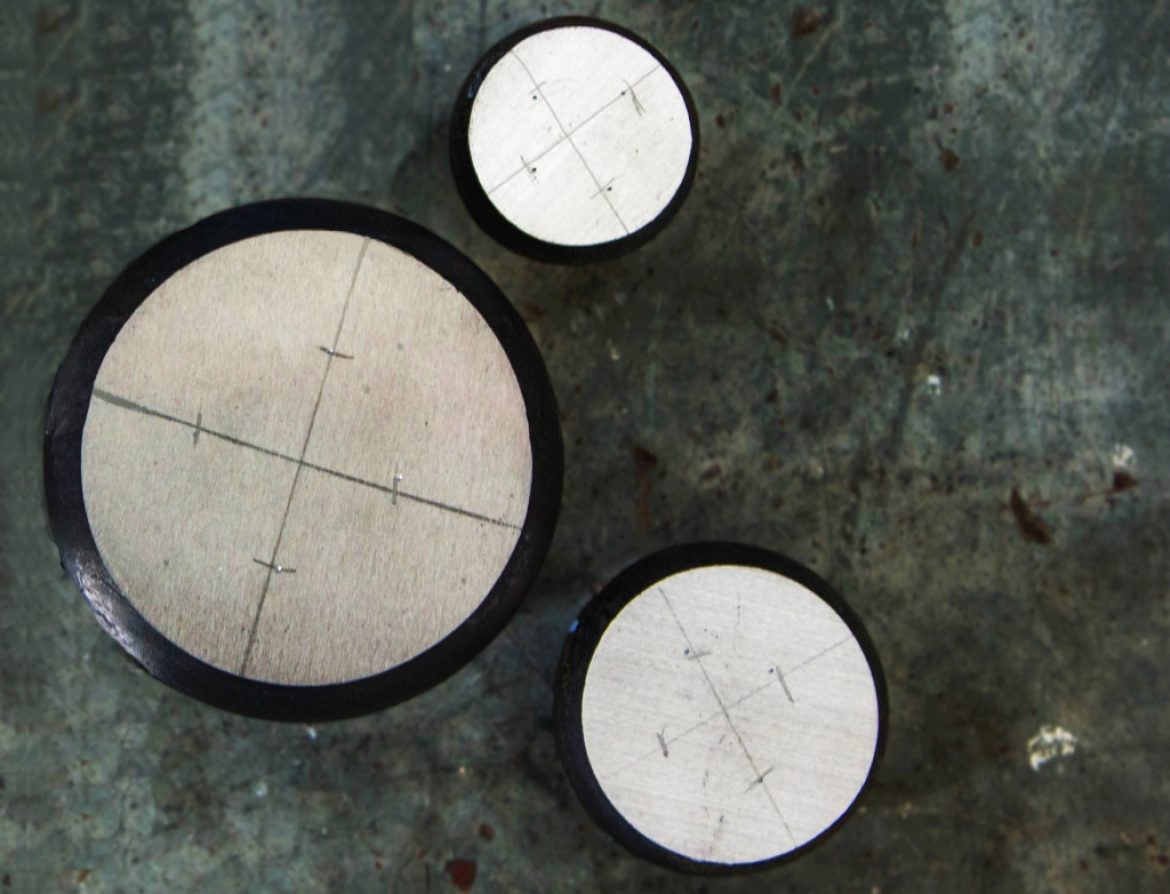

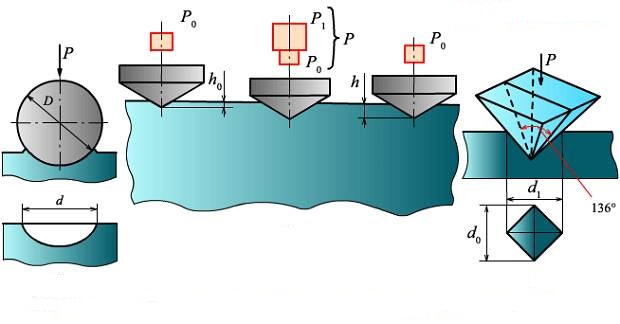

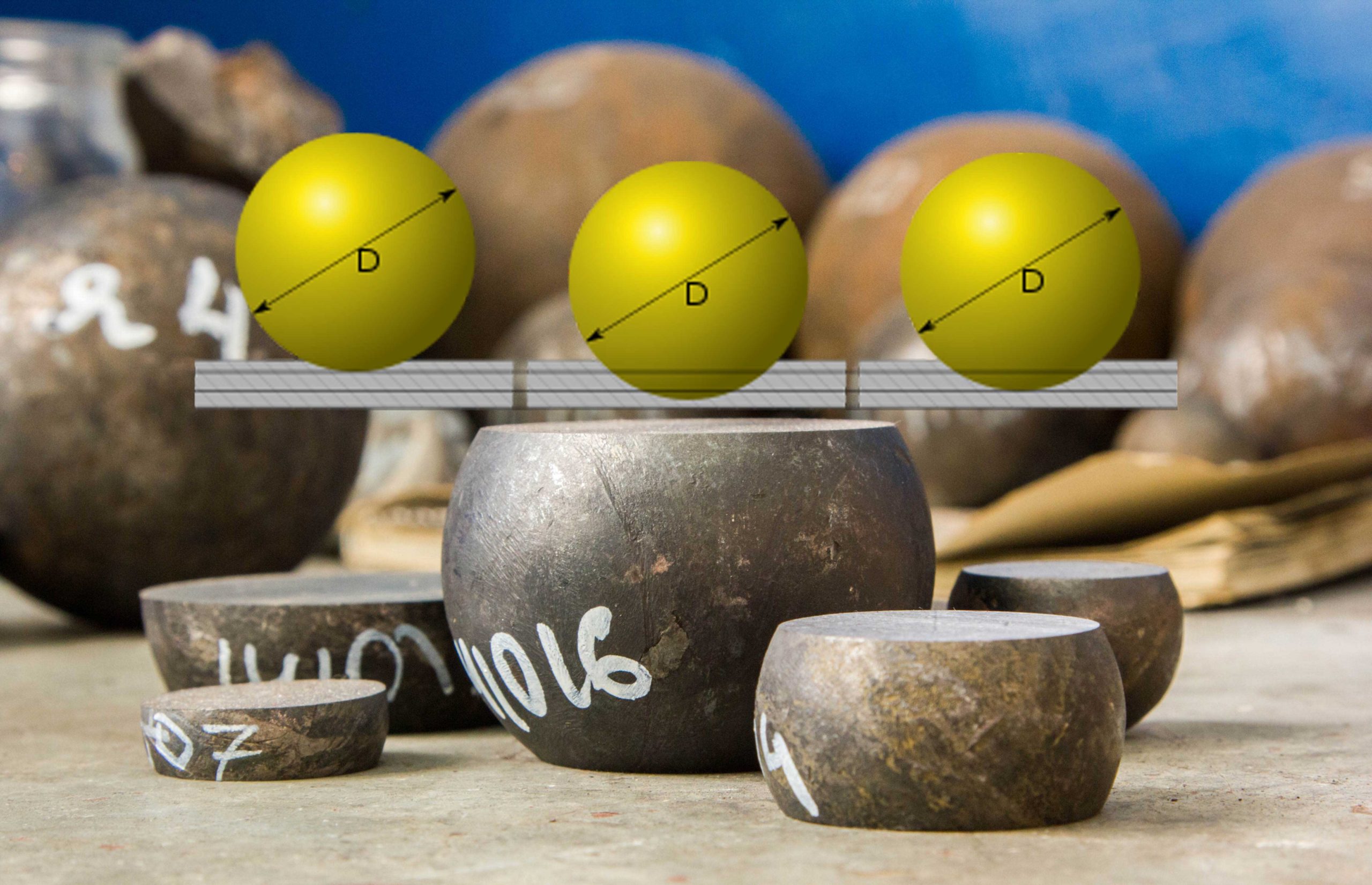

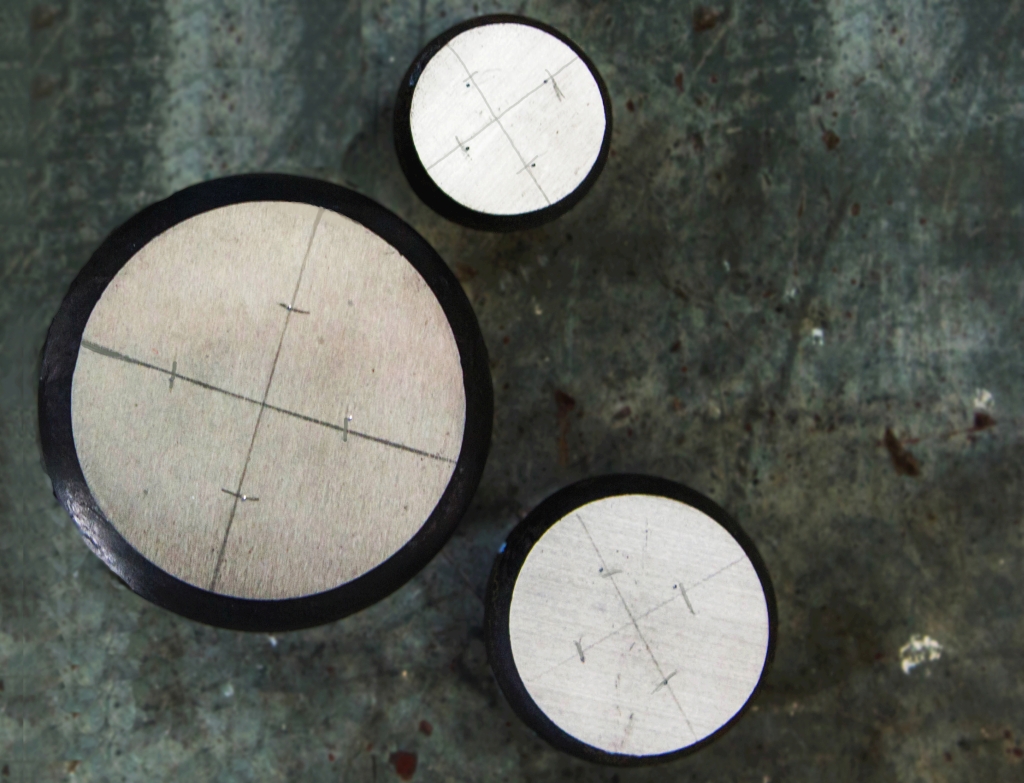

A certain number of grinding balls are selected from each batch produced during the production process. Each ball undergoes testing for surface and volumetric hardness. If it is necessary to confirm or clarify the measurement results, or to conduct microstructural and metallographic analysis, the grinding balls are additionally sent for independent examination.

Shock resistance of the grinding balls is also monitored using a pile driver installed specifically for this purpose. The impact energy is calculated based on the loads the balls experience in a mill. Each batch of products undergoes standard shock resistance testing to eliminate the risk of breakage during operation.

The factory is also working on installing equipment to perform comparative wear resistance tests on grinding balls made from different steel grades. Additionally, it is possible to manufacture grinding balls according to customer specifications, including required surface and volumetric hardness, as well as the number and energy of impacts.