As we have written it before, there are two methods for determining the grinding balls bulk weight in a mill:

- Method with complete grinding media discharge from the mill inner drum.

- Method without unloading grinding balls.

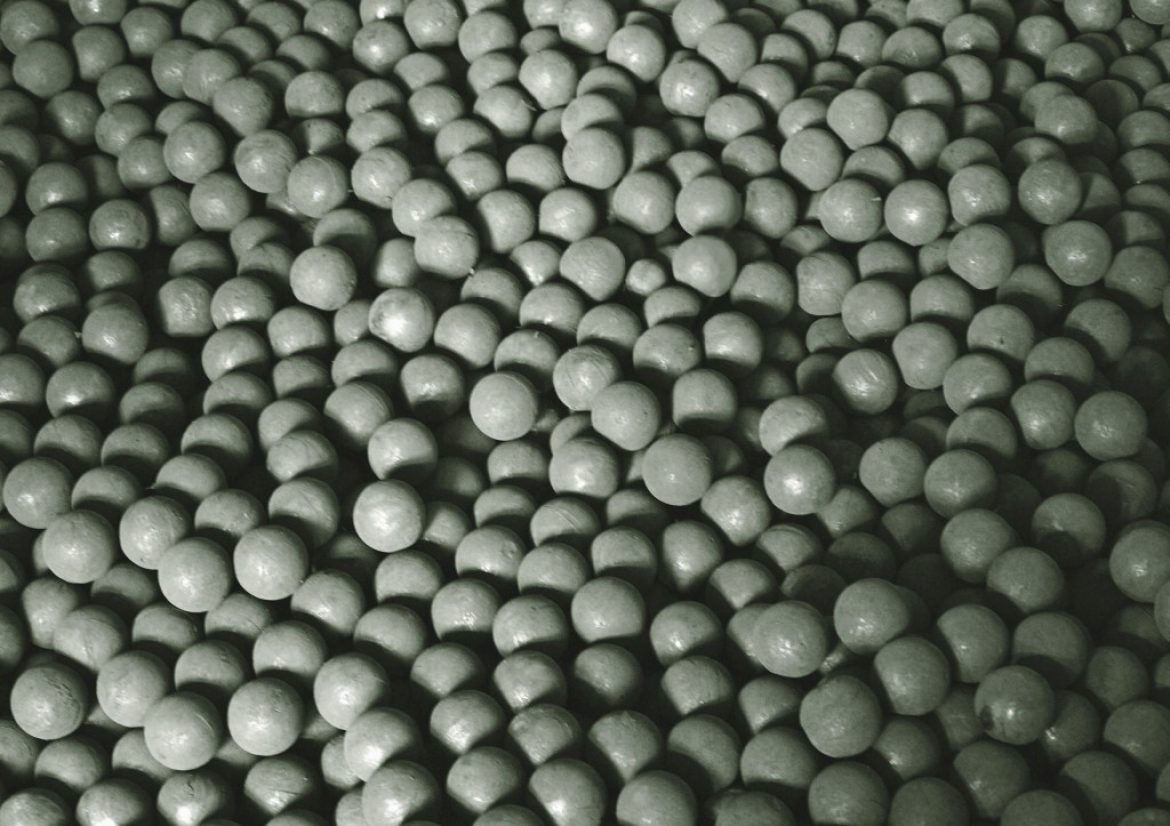

In the previous article we considered the 1-st method for determining the bulk weight of grinding media. This article analyzes the second method. The 2-nd method is less labor-intensive, but has a small error, because the sampling is no more than 5% of total volume the grinding media in the mill.

Unloaded grinding balls sorted by classes – gradation by diameters. The gradation scale selected in steps of 10 mm.

Each class (diameter) is weighing after sorting. Next, determines the average grinding balls diameter in the mill by the weighted average value.

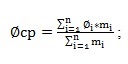

The formula for calculating the average grinding balls diameter in the mill

∅ср – the average grinding balls diameter, mm;

∅i – the maximum grinding ball diameter in each class, mm;

mi – the grinding ball mass of each class, kg.

Then, selected samples placed in a container and re-weighed. Capacity should have no flaws (“waves”, protrusions, holes, etc.) and container form must be of the correct geometric shape (cube or parallelepiped). Compliance with these conditions is necessary for the correct calculation the volume of container.

Importantly, the selected samples must completely occupy the entire container volume (capacity volume = grinding media volume). Complied the proportion according to which calculated the grinding balls bulk weight (the grinding media mass in one cubic meter). The general formula presented below.

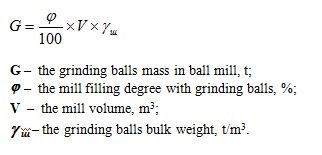

The formula for calculating the grinding balls mass in ball mill

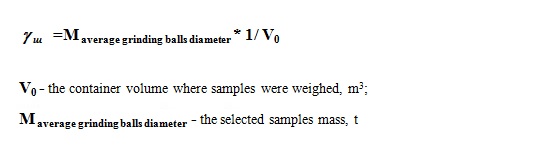

The grinding balls bulk weight (gш ) calculated by the proportion:

From the proportion follows: