We considered the preparation Methodology for conducting industrial tests in our last publication. The next step is industrial test conduction. During the entire test period, the tested mills work in the normal mode, all the requirements prescribed in the Methodology must be observed. Responsible persons at the enterprise should daily provide all current information on the mill’s performance – the productivity, the preloaded grinding media quantity, etc. by any convenient mode (by phone, e-mail, etc.).

It is very important to correctly and accurately measure the grinding media quantity in the mill during industrial tests. Measurements perform in mill by measuring the following parameters:

- the mill inner drum diameter;

- the mill inner drum length;

- the distance from the drum mill center to the surface of grinding balls.

Measurements taken at three points: mill power point, at mill center point and in mill unloading point.

Two measurements are taken at each point: first measurement make in the “hollow” between the armor plate lifters, the second measurement make on the uppermost part of the armor plate lifter. Then, the obtained measurements averaged (by the arithmetic mean) and used in further calculations. The measurements can make by any measuring device – laser or ordinary tape.

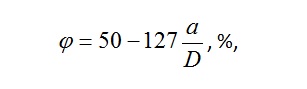

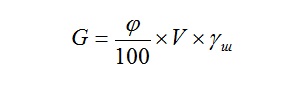

The grinding media filling degree and the total load weight (G) determined by the measurements results according to the following formula:

a – distance from the drum mill center to the surface of grinding balls, mm;

D – is the mill diameter in the light, mm.

V– the mill volume, m3;

γш – the grinding balls bulk weight in the embankment, t/m3.

The grinding media filling degree should be kept constant within the limits set by the technological instruction for the grinding process. It is desirable to make such measurements at least twice a month. During the measurements, representatives by both sides involved in industrial tests, perform the grinding balls visual state assessment, make measurements necessary for calculation the grinding balls quantity in the mill. The grinding balls quantity loaded in the mill adjust by the measurements results.

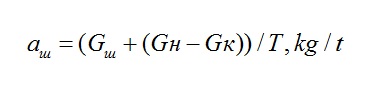

Necessary calculations make after the industrial tests finish. The grinding media specific consumption determined by the formula:

где: аш – the grinding media specific consumption per ton of crushed material behind the indicators determination period, kg / t.

Gш– the grinding media mass consumed for the calculation period, kg

GH– the grinding media mass in the mill at the initial period the indicators calculation, kg

GK– the grinding media mass in the mill at the final period the indicators calculation, kg

T – the recycled material amount during the calculation period, t

The technical council holds after industrial tests summing up. Here, the commercial and technical services specialists comprehensively consider the possible economic effect of use testing grinding media.

Energosteel Company experts have conducted many different industrial tests with grinding balls by Energosteel production for ten years experience in the grinding media market. The tests performed at: mining and processing plants, cement plants, aerated concrete production plants and thermal power plants. Each industry has own specificity for the industrial tests conduction, but due to the well-coordinated work the Energosteel Company specialists and our clients’ employees, we can achieved the most accurate industrial tests results subsequently brought an exceptionally positive economic effect to our customers.