The F. Bond ball mill

We continue to consider the methods of grinding process planning based on the calculations of different energy indexes. In this article, we are going to consider the methodology for calculating index, which has a direct impact on the choice of SAG mills when engineering the grinding process.

ВWi is the ball grinding work index. It is used to calculate the energy input (kW*h/t), that is needed to grind one ton of material of certain size (F100) in ball mill (D= 2,4 m) being in closed cycle with circulating loading 250 %.

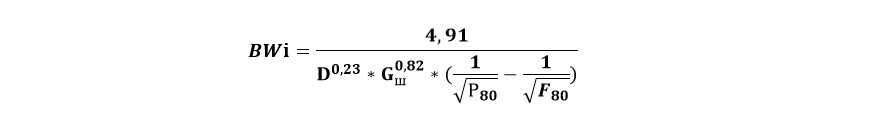

The formula for calculation the ВWi index is as follows:

Where G is material grindability at the ball mill (g/r);

F80 and Р80 – the mesh size whereby 80% of material is sieved in starting material and industrial product, respectively.

There is usually a weight (15-20 kg) on 3,35 mm size to conduct the laboratory test. The material is grinded in the laboratory ball mill (305 х 305 mm) by dry method (without adding water). The weight of loaded grinding balls is 20-21 kg. The grinding balls selecting should to consist of grinding balls of different diameter to achieve the most accurate data.

In that way, using these obtained results, it is easy to choose an industrial equipment that will be most effective in grinding process under specific conditions.