To date, only two enterprises in Ukraine use vertical mills: one is a cement producer and the other is a ore-processing plant. Both enterprises have been reliable partners of Energosteel Company for more than 10 years.

This type of mill is used to achieve maximum grinding of the material. As a rule, the finesse of grinding is in the limit of minus 20 microns. The capacity of such mills shall not exceed 6mm.

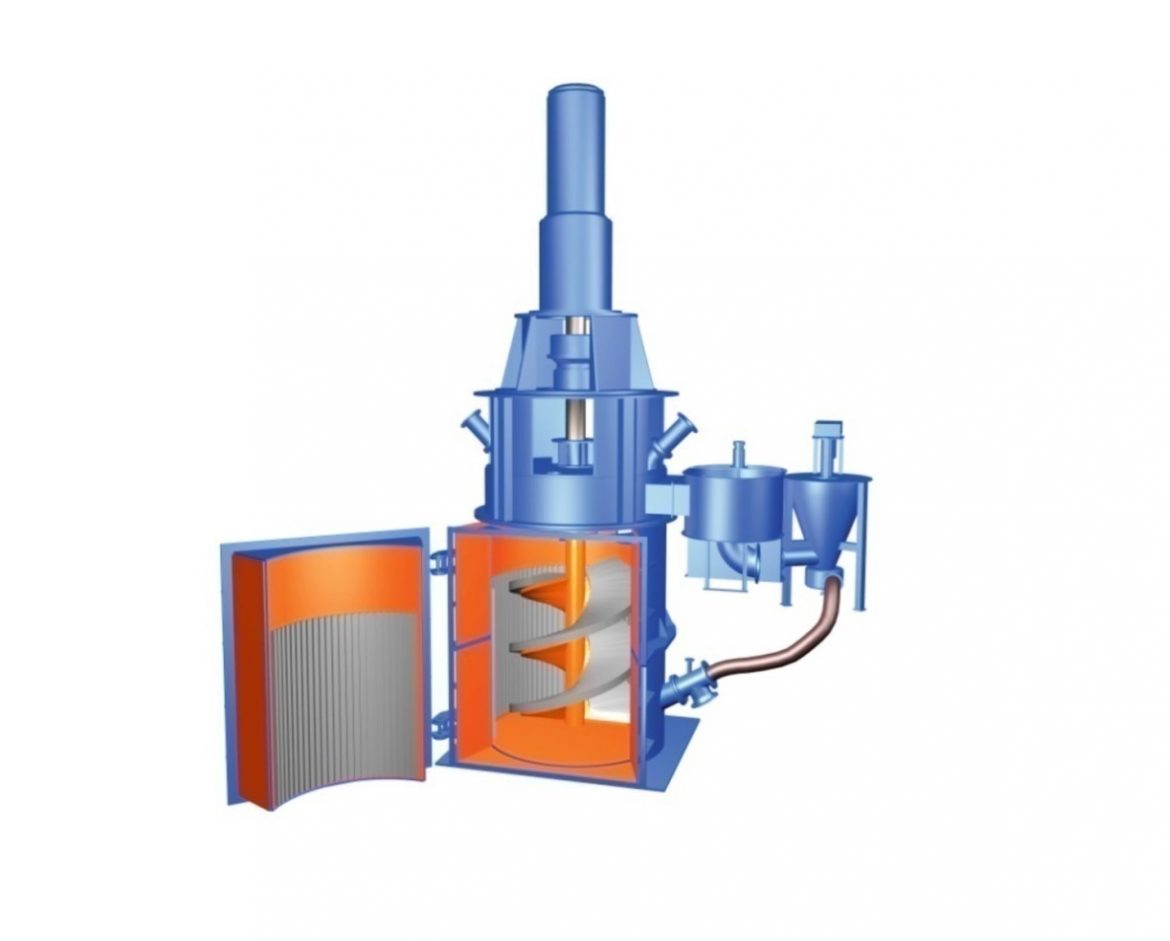

The grinding in such mills takes place in a vertically arranged screw which rotates and mixes the material with grinding media – steel grinding balls of 11-20mm in diameter.

Such mills are seldom refilled. This is due to some technical inconvenience and the long waiting period for such work. Therefore, to maximize the economic impact of such mills, only high-quality grinding balls should be used.

At the moment Energosteel Company is negotiating the possibility of carrying out industrial tests – application of steel grinding balls of our manufacture.

To sum up, we note that the Vertimills belong to the equipment of thin grinding. For efficient operation, the grinding material should be shredding in the ball mills.