Tech support from „Energosteel”: monitoring of every rotation

In the industrial world, where every rotation matters and every detail is significant, manufacturer tech support becomes a crucial element of success. This applies also to […]

THE DETERMINATION OF THE RATE OF GRINDING BALLS LOADING

The grinding process in ball mills (where grinding balls are used as grinding medium) is one of the widely used methods in practice to reduce the […]

QUESTION: CYLPEBS OR BALL?

We have repeatedly given evidence that the use of grinding balls in grinding material is more effective than the use of a cast iron cylpeb. Since […]

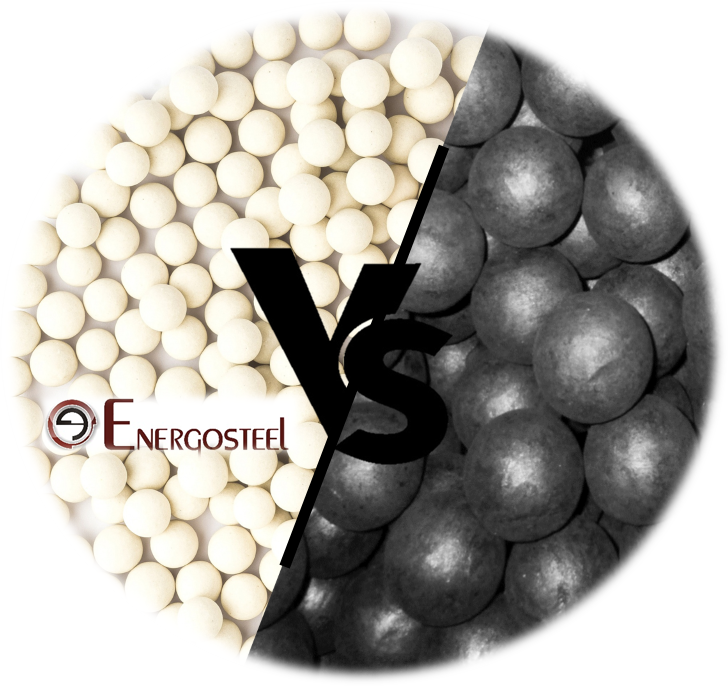

COMPARISON OF SPECIFIC CONSUMPTION RATE OF CERAMIC AND STEEL GRINDING BALLS

We recently announced that we have researched the ceramic ball market. We were very interested in this niche. Having understood in detail the technology of using […]

RE-GRINDING AS A QUALITY IMPROVEMENT TOOL

The high quality of products is the key to successful competition in the market. Therefore, each manufacturer pursues two goals: cost reduction and improvement of quality […]

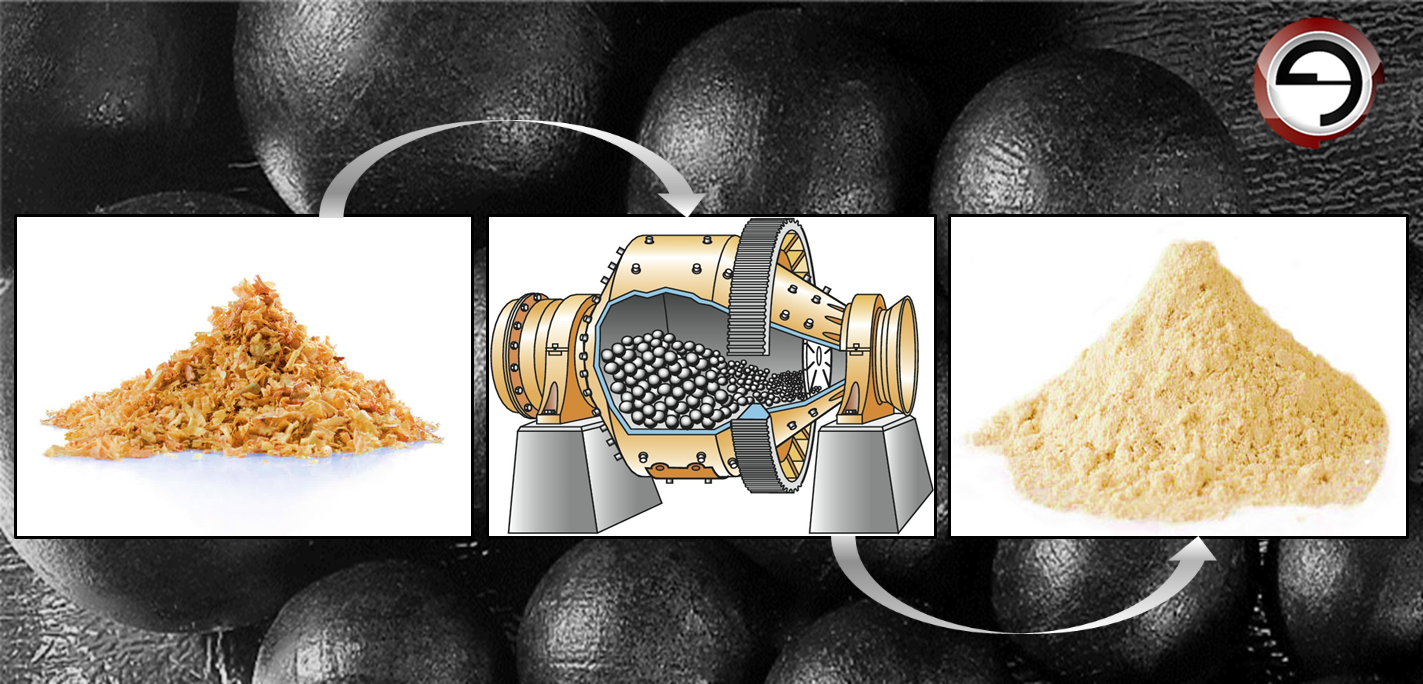

THE CELLULOSE GRINDING

We continue to introduce our readers to interesting queries that come to us for miscalculation of grinding balls assortment. The first request, in 2022, came from […]

BOND LABORATORY MILL

In September, our company received a request to calculate the cost of grinding balls assortment. The composition of the assortment was specified in the request: Steel […]

THE INTERNAL STRAINS IN GRINDING BALLS

In the selection of grinding balls, the consumer is mostly based on hardness (hardness group) and chemical composition of the balls. The selection does not take […]

HOW DO THE ALLOYING ELEMENTS AFFECT THE GRINDING BALLS WEAR?

For the production of grinding balls, Energosteel uses hot rolled round bar from medium and high carbon and low-alloyed steel according to DSTU 8538: 2015. Alloying […]