STEEL GRINDING BALLS

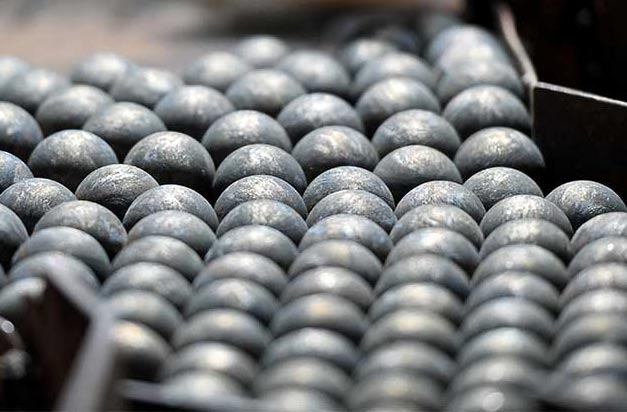

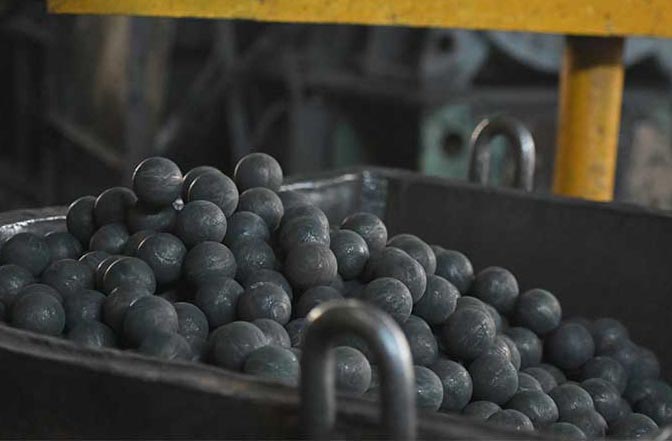

You can buy steel grinding balls with a diameter of 20mm to 125mm with a high carbon content and the volumetric hardness from 60 to 65 HRC. Click here to read technical specification.

All our gridning balls are manufactured in accordance with strict quality standards. Our production process is ISO certified and based on modern technologies. You can learn more about our manufacturing process to understand why our grinding media consistently show top-tier performance.

We are committed to making steel production both efficient and environmentally responsible. That’s why we introduced EcoBalls – a new generation of steel grinding balls manufactured entirely from recycled steel (scrap metal).

Beyond the product itself, we offer a full range of technical support services to help you select the optimal grinding media size, hardness, and composition for your mill's specific needs. Our experienced engineers are ready to provide on-site consultations, mill performance evaluations, and grinding ball usage recommendations to ensure the best possible results.

We also understand that logistics flexibility is key for uninterrupted operations. That’s why Energosteel offers customized delivery solutions and packing. We work closely with each client to develop a delivery plan that aligns with your production timeline and warehouse capacity.

WHAT MAKES US DIFFERENT?

High-quality steel grinding balls

Technical support throughout the sales process and product operation

Warranty on the quality and performance of the balls

Tailored transport solutions

Flexible packaging options

Compliance and deadline management

European warehouse presence

Manufacture with minimal environmental impact

At Energosteel, we produce high-quality grinding media that not only enhance operational efficiency and durability, but also promote a sustainable future through our commitment to innovation, quality, and the use of recycled steel.