The right choice of grinding balls is the main factor that guarantees the achievement of maximum performance in the grinding process. There is a question: how to evaluate the grinding quality? There are several methods for determining this parameter.

The most common and simplest method for determining grinding quality is ‘sieve residue’ calculation.

The essence of the method is the determination of partial and full residues on standard sieves as a result of sieving the selected sample after the material grinding (for each case the set of sieves can differ, it depends on the grinding requirements according to the technological map of each enterprise).

To determine the granulometric composition of the material, the sample is dried when grinding occurs in a wet environment.

Consider a concrete example when the ground material is ordinary sand. Before sieving, weigh the sample and dry it. A set of sieves is prepared by placing sieves with larger openings above the sieves with smaller openings. The sieving consists of placing a sample onto a sieve with the largest diameter openings and agitating the sieve manually or mechanically.

In our case, we will use sieves with the following opening sizes: 2.5 mm; 1.25 mm; 0.63 mm; 0,315 mm; 0.14 mm.

A sieving is complete if falling grains of sand is not observed by shaking each sieve over a piece of paper.

Weigh the residues on each sieve and pan (where the smallest grains passed through a 0.14 sieve accumulate) .

After weighing carry out the following calculations:

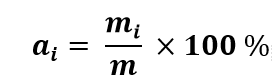

– determine the partial residue a,% on each sieve and pan:

where mi is the mass of the residue, g;

m is the total mass of the sand sample, g.

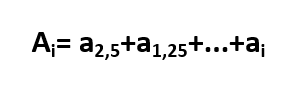

– determine the total residue on each sieve (Аi) %:

where а2,5, a1,25 – partial residues on sieves with a large diameter holes

ai – partial residues on this sieve.

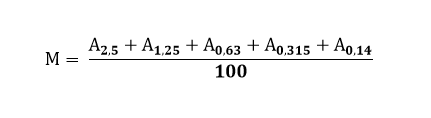

– calculate the material size module M

where A2,5,A1,25, A0,63, A0,315, A0,14 are the full residues on sieve.

After determining, the sand size module is divided into groups. The index of a very small sand size module is 1.5-1.0; small – 2.0-1.5; medium – 2.5-2.0 and large – 2.5 and higher.

In this case, we considered the determination of the grinding quality by the “residue on sieve” method.

Usually for the production of aerated concrete blocks, the grinding requirement is 13-20% of the residue on the sieve (the size of the sieve diameters is 8 microns).