In the previous article we considered the method for determining the bulk weigh of new grinding media. Determination the grinding balls bulk weigh directly operating in a ball mill becomes necessary on practice. It is done in order to accurately definition the grinding ball mass during measuring in a ball mill and exclude the mill overloading with grinding balls possibility

There are two methods for determining the grinding balls bulk weight in a mill:

- Method with complete grinding media discharge from the mill inner drum.

- Method without unloading grinding balls.

Calculations by the first method are most accurate, but require a lot of labor costs and time.

In this article, we will consider the technique for determining the grinding balls bulk weight in fully unloaded mill. This method used in the mills repair (armor plates replacement). The grinding balls unload from the mill into a special pit (needs to open hatches and pour the grinding balls from the drum during mill scroll). Then, need to definition maximum and minimum grinding balls diameter located in the mill. Unloaded grinding balls sorted by classes – gradation by diameters. The gradation scale selected in steps of 10 mm. Sorting can be done manually (samples measured by a caliper in diameter and visually sorted by classes comparing with other balls size) or by the screen use.

Each class (diameter) is weighing after sorting. Next, determines the average grinding balls diameter in the mill by the weighted average value.

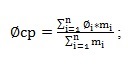

The formula for calculating the average grinding balls diameter in the mill

∅ср – the average grinding balls diameter, mm;;

∅i – the maximum grinding ball diameter in each class, mm;

mi – the grinding ball mass of each class, kg.

The grinding balls bulk weight determined by using tabular data. The grinding balls bulk weight corresponds to the calculated average grinding balls diameter in the mill. Calculated (tabular) data of the steel grinding balls bulk weight present in the tables of the following specialized printed publications:

- Olevsky V.A., Grinding equipment of concentrating plants, Moscow – 1963.

- Bogdanov O.S., Handbook of ore enrichment, Moscow – 1982.

The calculated steel grinding balls bulk weight shown below in the table. Please note the calculated bulk weight may differ from the actual weight. This depends on several factors: the material of the grinding media, the range by geometric dimensions.

The table. The grinding balls bulk weight (steel density 7.85 t/m3).

| Diameter, mm | Weight of 1m3 grinding balls, t |

| 30 | 4,85 |

| 40 | 4,76 |

| 50 | 4,70 |

| 60 | 4,65 |

| 80 | 4,60 |

| 100 | 4,56 |

| 125 | 4,52 |

Thus, during calculating the grinding balls mass in ball mill (after measuring the mill filling degree with grinding media) needs to use the grinding balls bulk weight whose diameter was determined earlier. In this case, it may be differ from the grinding balls bulk weight loaded to the mill. The formula for calculating the grinding balls mass in ball mill is given below (we will consider the measurements process and calculations in more detail in our next articles).

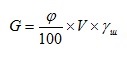

The formula for calculating the grinding balls mass in ball mill

G – the grinding balls mass in ball mill, t;

j – the mill filling degree with grinding balls, %;

V – the mill volume, m3;

g ш – the grinding balls bulk weight, t/m3.

The correct determination of the grinding balls bulk weight in mill allows accurately determination the mill balls feed weight. The mill balls feed weight is necessary for calculating the grinding media specific consumption and avoid mill overloading, thereby eliminating the motor load increasing possibility.